Cured-In-Place Pipe Lining Experts.

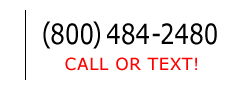

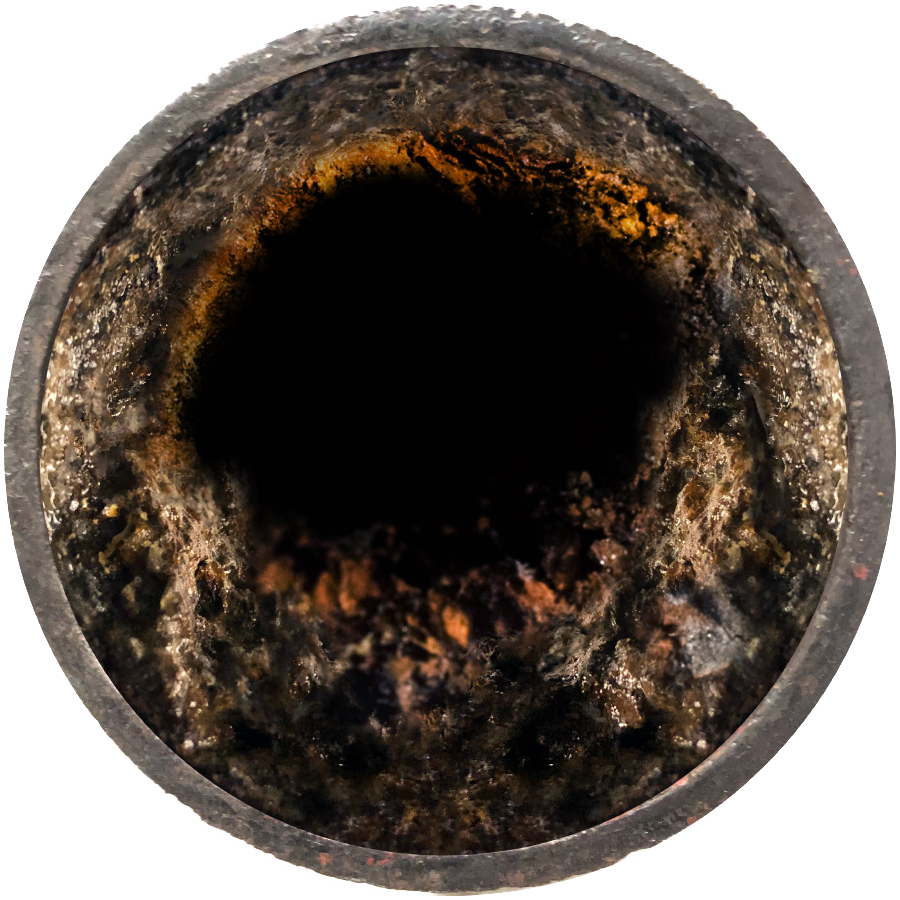

Champion restores pipes from within by installing composite pipes inside of failing pipes. Pipe Lining provides a permanent solution without excavation. It’s a highly specialized process. . . and we’re good at it.

-

No Joints to Fail

-

Improved Flow Dynamics

-

Lasting Structural Composite Pipe

-

Eliminates Root Intrusion

Step 1 – Liner Wet Out

A tube comprised of multiple layers of poly-textile with a water-tight barrier membrane is carefully measured and cut to length.

Prepared resin is weighed and a pre-calculated amount is poured into the dry tube.

Vacuum is applied to the end of the tube while it is fed through calibrated roller equipment to ensure uniform saturation of the material with resin.

Step 2 – Installation

There are several methods for installing liner into pipe. In most cases, the resin-saturated tube is loaded into a pressure drum outfitted with an inversion nozzle.

As air pressure is added to the drum, the liner inverts, like reversing a sock, dispensing the liner into the pipe.

The inversion places the wet resin that was previously inside of the tube in contact with the pipe wall.

Step 3 – Curing

The installed liner is held in place by maintaining the internal pressure.

Depending upon the resin system utilized, the newly installed liner is cured using ambient chemistry, applied heat, or ultra-violet light.

As liner cures, it bonds with the pipe wall and hardens to form a PVC-like pipe within the host pipe.

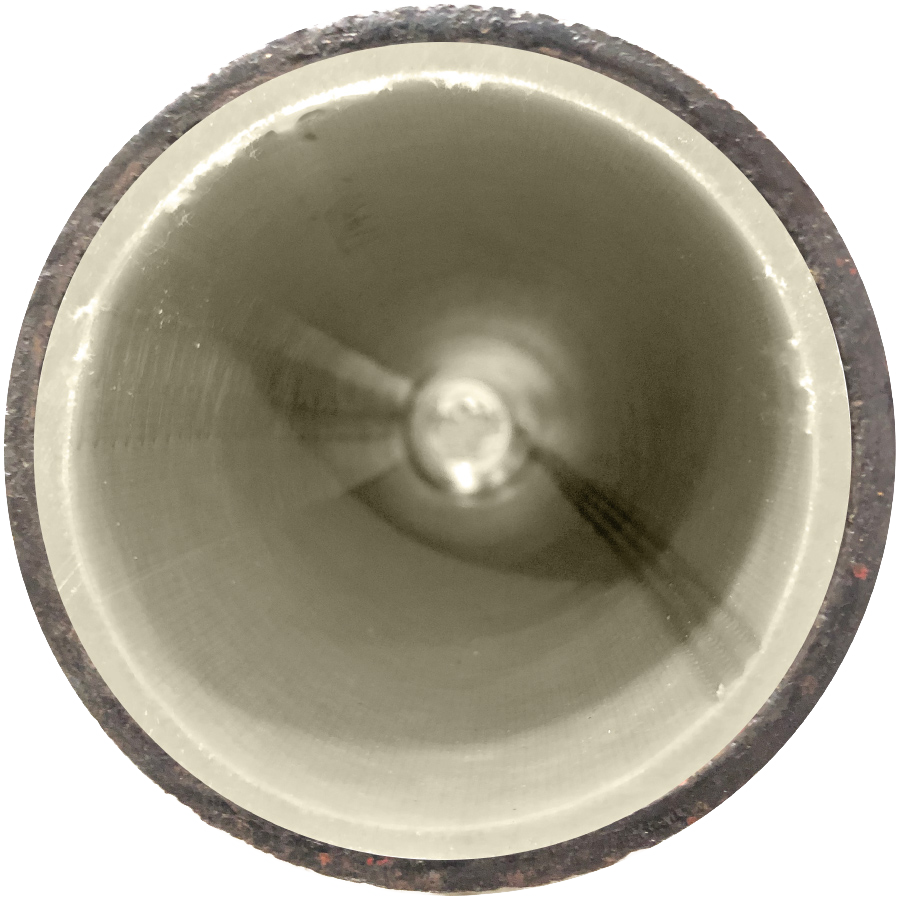

Step 4 – Reinstatement

Once the liner is fully cured, any branch lines or service connections that have been covered over by the liner must be opened up again.

Champion utilizes state-of-the-art robotic tooling to cut away obstructing liner material and reinstate service connections.

After reinstatement, the restored pipe is ready to be returned to service.

Pipe Lining is Suitable For MULTIPLE APPLICATIONS

Residential & Commercial Plumbing

Under-Slab Sewer Pipes

Failing Cast-Iron, Clay (terra-cotta), and PVC Sewer

Lateral Connection Lines from Building to Municipal

Vertical Stacks

Condos & Multi-Story

Soil and Waste Stacks

Vent Stacks for Sewer, Grey, and Rainwater Systems

Roof Drains and Stormwater Stacks

Industrial Piping

Sewer Plant Clarifier Drain Lines

Heating & Cooling System Lines (glycol & chemical resistance)

Fluid Delivery Piping

Storm Drains

& Sewer Mainlines

Stormwater Drainage Lines (RCP, Clay, PVC, etc.)

Sewer Mainlines and Collector Pipes

Municipal

High-Tech Composite Materials Make Trenchless Pipe Restoration Possible.

The cutting-edge resins and textiles used by Champion Pipe Restoration are of the same class of materials used to manufacture modern spacecraft, airplanes, boats, and high-performance vehicles.

Lining pipe with composite materials produces strong, plastic-like pipes within failing pipes that will endure decades of continued service.

Lined pipe is smooth, durable, and resistant to a broad range of household and industrial chemicals.