More Options. Less Down Time. Lower Cost. Lasting Results.

Advanced pipe lining technologies such as Cured-In-Place Pipe Lining and Resin Coating allow Champion Pipe Restoration to repair pipes where traditional plumbing methods can’t. Our Speed, Minimal Footprint, and Unique Capabilities deliver results with less down-time and disruption.

How We Give New Life To Old Pipes…

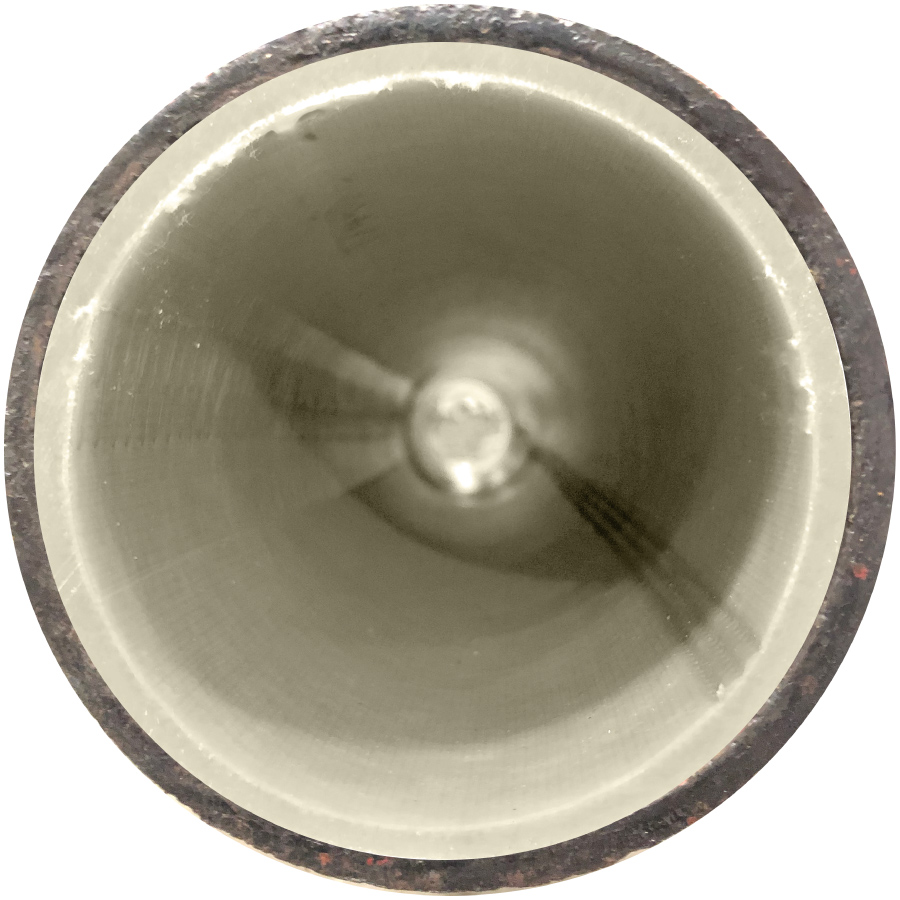

Our experienced professionals will renew your pipe systems from the inside by creating new pipes within your original pipes. For 1.5-2″ diameter pipes, specialized equipment is used to apply a durable epoxy coating to the inside of pipe walls, sealing leaks and protecting the pipe from further degradation. For 2-8″ pipes, a resin saturated liner is pulled or inverted into the host-pipe and then cured to create a new composite pipe within the original pipe. Our environmentally friendly methods require little to no digging or disruption and provide a long-lasting solution to your pipe problems.

In most cases, individual pipe sections and branch lines can be restored and reinstated in a

SINGLE DAY, returning lines to service each day before our crews leave.

To learn more about our amazing technologies, Click Here.

Dedicated To Helping You Minimize Costly Down-Time.

Faster Restoration Keeps Operations Moving

Depending upon the extent of the work to be performed, most pipe sections can be restored and returned to service in a single shift. This means you’ll be back in business when our crews leave for the day. Because our services are non-destructive, our footprint is small.

Flexible Scheduling Minimizes Down-Time

We’ll work when you don’t have to. We understand the importance of keeping operations flowing and customers satisfied. We can schedule pipe restoration work to be performed at night, on weekends, or when operations are slowest.

Pipe Restoration For A Wide Range of Industrial Applications

Industrial Plumbing Systems

Compatible Pipe Materials

Benefits of Our Internal Pipe Restoration Methods

Advanced Restoration Technologies For Results That Last

Champion Pipe Restoration employs a straight-forward, Proven Process to restore industrial pipe systems with greater flexibility and less disruption than traditional pipe removal and replacement methods. Our experienced professionals will renew your pipes from the inside by creating new pipes within your existing failing pipes.

STEP 1

Preliminary

Video Inspection

STEP 2

Pipe Cleaning

& Preparation

STEP 3

Pipe Lining & Epoxy Coating

STEP 4

Reinstatement of Connections

STEP 5

Post-Restoration Inspection

Learn more about our amazing pipe restoration technologies or

get started today by scheduling a Site Visit.

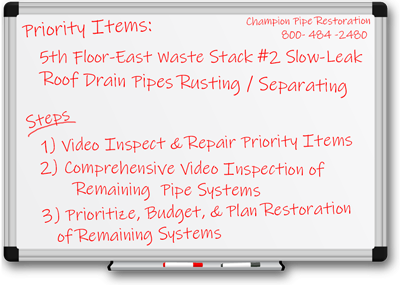

It’s Easy to Get Started. Here’s How…

- Call or Message us to schedule a site visit.

- We’ll provide you with a Restoration Plan that explains the cost/benefit of any options and takes your budget into account.

- With your approval, we’ll perform restoration work on a schedule that has the least impact on your operations.

When we’re done…you can relax knowing that our work is backed by a 5 Year Warranty and your new pipes have a design life in excess of 50 years.